Manufacturing

We use several different methods of manufacturing for our aerospace fastener lines:

- - Head forging

- - CNC machining

- - Centerless Grinding

- - Thread Rolling

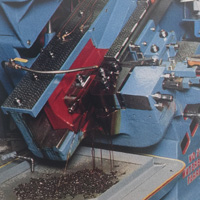

Cold and hot head forging methods are used to manufacture our wide variety of standard and oversize fasteners. These include the Hi-Lok™ and Hi-Tigue™ fasteners, straight shank pins, customer special orders and our new, light-weight Ultra-Lite™ fastener.

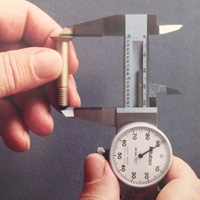

Inspection

Production Processes

Cold and hot heading and secondary operations are used to finish the fastener blank.

Typical finishing methods include:

- Head turning and trimming.

- Endpoinnting.

- Drilling and broaching the hex recess in the thread end of the Hi-Lok™ and Hi-Tigue™ series Fasteners.

- Precision centerless grinding.

- Tapping

of the expander nut and Hi-Lok™ collars.

- Filet rolling, which is the controled cold working of the shank to the head filet radius.

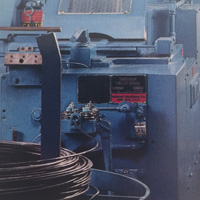

- Hot and cold Thread rolling is done using the two-die reciprocating method, and

Reed thread rollers are used for larger diameters.

These finishing methods also include Hi-Kote™1 and Hi-Kote™2 and other plating methods.

Heading machine

Thread Roll Machine